Minimise your environmental impact and ensure regulatory compliance with our expert effluent treatment solutions. We specialise in treating both liquid and gaseous effluent streams, leveraging advanced technologies and proven processes to effectively target and remove radioactive contaminants.

Modular, adaptable and rapid-deploy systems for efficient removal

of radioactive contaminants from complex effluent streams

Our solutions include...

Solution engineering, design, build, and operation

From concept design to ongoing operation, we craft solutions to meet your exact needs, backed by comprehensive test and qualification services for guaranteed performance.

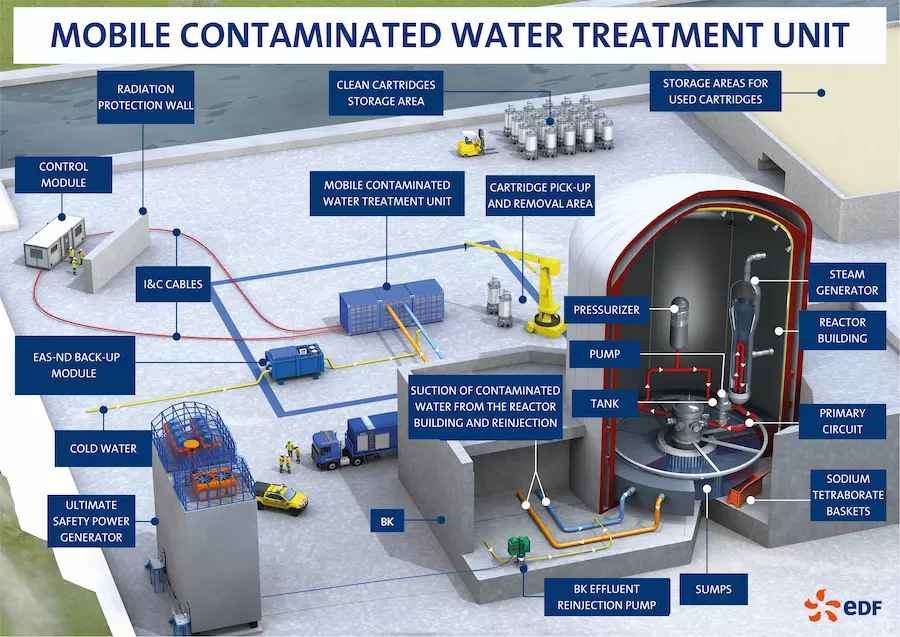

Modular mobile units

Our mobile treatment systems offer flexibility and rapid deployment to sites where permanent infrastructure is impractical.

Ion exchange or sorbants

We use advanced ion exchange resins and sorption media to selectively remove target radioisotopes from effluent streams.

Evaporation

Our evaporation systems efficiently concentrate liquid radioactive waste, reducing volume and facilitating safer disposal.

ActifloRad (mixer/settler)

Successfully deployed to the Fukushima Daiichi site following the 2011 incident, our ActifloRad technology enhances flocculation and sedimentation processes for highly effective removal of radioactive contaminants from water.

Tritium Management

Veolia's fully licensed MDS® is an innovative, versatile tritium management system. As fusion energy drives interest in tritium, MDS® efficiently treats light water to recover and valorise tritium. The modular system operates across various concentrations and flow rates, meeting current and future industry needs.